|

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

ACO Drain

|

|

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

hh

|

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| KlassikDrain | K100 |

KS100 |

K200 |

KS200 |

K300 |

KS300 |

| Channels & In-line Pits | ||||||

| Plastic Intercept Heelsafe |

||||||

| Steel Slotted Grates (Class A) | ||||||

| Stainless 5 Star Heelsafe |

||||||

| Galvanised Longitudinal Heelsafe |

||||||

| Galvanised Transverse Grates (Class B) | ||||||

| Plastic Slotted Heelsafe |

||||||

| Steel Slotted Grates (Class D) | ||||||

| Steel Mesh Grates (Class D) | ||||||

| Iron Wave Heelsafe |

||||||

| Iron Slotted Grates (Class D) | ||||||

| Iron Intercept Heelsafe |

||||||

| Iron Galvanised Intercept Heelsafe |

||||||

| PowerDrain | S100K |

S200K |

S300K |

|||

| Channels & In-line Pits | ||||||

| Iron Intercept Heelsafe |

||||||

| Iron Slotted Grates (Class G) | ||||||

| Iron Intercept Heelsafe Anti-Slip Grates (Class G) | ||||||

| SlabDrain HK Series | H100K / H100KS |

H200K / H200KS |

H300K / H300KS |

|||

| Channels | ||||||

| Plastic Intercept Heelsafe |

||||||

| Steel Slotted Grates (Class A) | ||||||

| Stainless Wedgewire Heelsafe |

||||||

| Stainless 5 Star Heelsafe |

||||||

| Stainless Twinwire Heelsafe |

||||||

| Stainless Splitwire Heelsafe |

||||||

| Galvanised Longitudinal Heelsafe |

||||||

| Galvanised Transverse Grates (Class B) | ||||||

| Plastic Slotted Heelsafe |

||||||

| Steel Slotted Grates (Class D) | ||||||

| Steel Mesh Grates (Class D) | ||||||

| Iron Wave Heelsafe |

||||||

| Iron Slotted Grates (Class D) | ||||||

| Iron Intercept Heelsafe |

||||||

| Iron Galvanised Intercept Heelsafe |

||||||

| SlabDrain HSK Series | H100SK |

H200SK |

H300SK |

|||

| Channels | ||||||

| Iron Intercept Heelsafe |

||||||

| Iron Slotted Grates (Class G) | ||||||

| Brickslot | K100 |

KS100 |

H100K / H100KS |

|||

| Channels | ||||||

| Steel Brickslot (Class D) | ||||||

| MiniKlassik | M50K / M50KS |

|||||

| Channels | ||||||

| Stainless 5 Star Heelsafe |

||||||

| Iron Intercept Heelsafe |

||||||

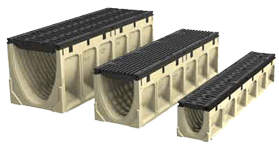

KlassikDrain

|

KlassikDrain

|

K100/KS100

|

K200/KS200

|

K300/KS300

|

PowerDrain

|

PowerDrain

|

S100K

|

S200K

|

S300K

|

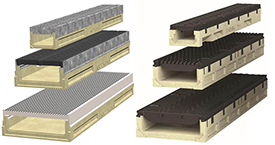

SlabDrain (HK Series)

|

H100K/H100KS

|

H200K/H200KS

|

H300K/H300KS

|

|

SlabDrain (HSK Series)

|

H100SK

|

H200SK

|

H300SK

|

|

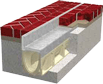

Brickslot System

|

KlassikDrain K100

|

SlabDrain H100K

|

||

MiniKlassik

|

M50K/M50KS

|

M100K/M100KS

|

||

Chemical Resistance

ACO Drain channel bodies are highly resistant to chemical attack and, with the appropriate grate, can be used in most environments where acids and dilute alkalis are encountered.

ACO Drain channel bodies are highly resistant to chemical attack and, with the appropriate grate, can be used in most environments where acids and dilute alkalis are encountered.

Refer to chemical chart below for resistance of Polyester polymer concrete. Standard products are manufactured using polyester resin.

These recommendations are for guidance only. Customers are advised to test a sample of polymer concrete to ensure suitability. Test samples are available free of charge from ACO.

Important considerations for chemical environments

When reviewing potential applications of trench drains in chemical environments, the following issues should be considered;

- Type(s) of chemical(s), including mixture composition %.

- Concentration percentages.

- Contact time with trench system.

- Temperatures of chemicals flowing into the trench drain. (82°C max).

- Flushing system employed to clear chemicals from the system.

- Cleaning agents should be checked for compatibility with trench materials.

- Test samples can be used for final determination of chemical resistance.

- Grate, locking mechanism, edge rail, outlet and rubbish basket materials should be checked for chemical resistance.

- Check sealant for compatibility, if applicable.

| Chemical Medium | Conc |

72 Hours |

42 Days |

|

Acetic Acid Acetone Ammonia Aniline Aniline in Ethyl Alcohol Benzene Boric Acid Butyric Acid Butyl Alcohol Calcium Chloride Calcium Hydroxide Caster Oil Chloric Acid Chromic Acid Citric Acid Diesel Fuel Ethanol Ethlendiamine Ethyl Acetate Ferrous Sulfate Fluorallic Acid Formaldehyde Formic Acid Fuel Oil n-Heptane n-Hexane Hydraulic Oil Hydrochloric Acid Hydrofluoric Acid JP4 JP8 Lactic Acid Methanol Methyl Amine Methyl Ethyl Ketone Mineral Oil SAE5W50 Monochlor Benzene Monochloroacetic Acid Nitric Acid n-Nonane Iso-Octane Oxalic Acid Petrol Phenol Phosphoric Acid Potassium Hydroxide Sodium Acetate Sodium Carbonate Sodium Chloride Sodium Hydroxide Sodium Hypochloric Sulfuric Acid Tetrafluoroborsaure Toluene Trichloroethylene Triethylamine Xylene |

10% 10% 100% 10% 100% 100% 25% 100% 100% 100% 100% 5% 5% 100% 100% 100% 100% 100% 30% 10% 35% 10% 100% 100% 100% 100% 10% 5% 100% 100% 10% 5% 100% 100% 100% 0.05% 10% 10% 100% 100% 100% 100% 100% 10% 10% 100% 20% 100% 15% 5% 40% 20% 100% 100% 100% 100% |

Y Y Y Y Y Y Y Y Y Y Y Y Y Y Y Y Y Y Y Y Y Y Y Y Y Y Y Y Y Y Y N Y Y Y N Y Y Y Y Y Y Y Y N Y Y Y Y Y Y Y Y N Y Y |

N N N Y N Y Y Y Y N Y N Y Y Y N Y N Y Y Y N Y Y Y Y Y N Y Y Y N N N Y N Y N Y N Y Y N Y N N Y Y N Y Y N N N Y N |

|

Material Properties & Comparison

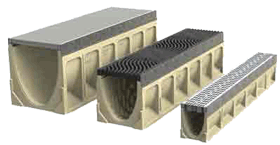

Modular trench drain systems are generally manufactured from either polymer concrete, GRC (glass fibre reinforced concrete) or HDPE (High Density Polyethylene). ACO Drain commercial grated trench systems are manufactured from polymer concrete. Other materials do not meet the compressive strength and thermal expansion properties required in commercial and industrial applications.

ACO only uses HDPE as a trench material for domestic applications.

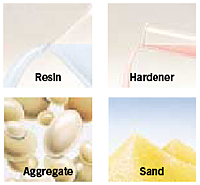

Polymer Concrete

Polymer Concrete

Polymer concrete is a versatile composite material produced by mixing mineral aggregates with a resin binding agent. The finished material has excellent mechanical and thermal properties and offers good corrosion resistance to many chemicals. A maximum working temperature of 82°C is recommended.

For increased chemical resistance, Vinyl ester polymer concrete is available. This consists of vinylester resin binder with superior silica aggregate fillers.

See chemical resistance chart for further details.

Due to their structural rigidity, polymer concrete trench drains, when installed properly can be used in a variety of pavement types such as concrete, asphalt and brick pavers.

GRC

GRC

Glass fibre reinforced concrete (GRC) is a mixture of cement, fine aggregate, water, chemical admixtures and alkali resistant glass fibres. GRC is predominantly used for building cladding panels.

Cement Concrete

Cement concrete is Portland cement mixed with aggregates. Generally used for large cast-in-situ slab applications, where mass is required for structural rigidity.

PE (Plastic)

PE (Plastic)

Polyethylene (PE) is the most common plastic used in trench drains. PE is a readily available, economical material that is easy to mould. PE has thermal properties that requires moulded features to key into the concrete. Without these features, and dependent on the short term temperature range, the trench may lose bond (pull away) from its concrete encasement and buckle.

Grates

Grates are manufactured from a variety of materials. The most common are ductile iron, mild steel, stainless steel and plastic. Grates need higher tensile properties than the trench body to withstand direct loads. Grates can be removed, changed or easily replaced after installation, unlike the trench drain body

For assistance with material properties of grates, contact our Technical Service Department using the Contact Us form, or call +61 2 4747 4000

| Mechanical Properties | Cement Concrete |

GRC |

HDPE |

|

| Compressive strength The trench body is subject to compressive loads in use and needs to withstand the specified load. |

25MPa |

96MPa C-579 |

50MPa |

58MPa D-695 |

| Flexural strength Affects site handling and when trench body is in areas where encasement and soils are suspect. |

3MPa |

27MPa C-580 |

12MPa |

15MPa D-790 |

| Tensile strength Not generally required in trench bodies, but relevant to grates. Used as material measurement. |

2MPa |

21MPa C-307 |

5.5MPa |

14MPa D-638 |

| Thermal Properties | ||||

| Water absorption The trench is designed to carry and collect liquids without contaminating surrounding soil/encasement. |

<3% |

+0.07% C-97 |

12% |

+0.31% D-570 |

| Freeze-thaw Inability to withstand freeze-thaw cycles causes surface spoiling and leads ultimately to trench failure. |

300 cycles maintain 80% structural integrity |

300 cycles modulus of elasticity 95.1% C666 |

modulus of elasticity unchanged |

223 cycles FAILED modulus of elasticity test C666 |

| Coefficient of expansion/contraction Excessive movement between trench and encasement materials creates unwanted stresses which may lead to failure. |

10 x 10-6 per °C |

45.6 x 10-6 per °C E831 |

20 x 10-6 per °C |

209.8 x 10-6 per °C E831 |

| Water vapour transmission WVT is measurement of water vapour flow through a material. Passage of water vapour may be critical in some instances. |

See water absorption test |

WVT 0.0364g/m2 - 1,592hrs E96 |

1 x 10-4 gm/s.MN |

WVT - 0.1392g/m2 1,592hrs E96 |

| Surface Properties | ||||

| Surface burning Trench systems are often used around petrol stations, chemical processing and interior applications and may be subject to fire. They should be non-flammable and not give off fumes or smoke. |

Non-combustible |

Flame spread : 0 Smoke density : 5 E84 |

Non-combustible Ignitability: P Fire propagation: 0 Flame spread: 1 BS476 |

After flame time : 390 seconds - fail UL-94 |

| Weathering The majority of trench drains are used in exterior applications. Ability to withstand adverse weather will ensure long service life (erosion, UV degradation etc). |

Good

depending upon proper curing |

2000hr exposure no change G-153 |

Similar to cement concrete. UV stable |

1000hr exposure no change G-154 FAILED TEST |

| Coefficient of friction (Manning’s) Any degree of friction will affect liquid flow to some extent, therefore the lowest value is desirable. |

n=0.013 |

n=0.011 |

n=0.012 |

n=0.010 |

| Chemical resistance Trench may be used for liquids other than water and in such circumstances, needs to be resistant to a variety of mediums. |

Poor |

Good |

Poor - better than cement concrete |

Good |

Key:![]() - Good

- Good ![]() - Acceptable

- Acceptable ![]() - Poor

- Poor

Polymer concrete values obtained from experimental data using ASTM testing procedures

GRC values obtained from Design, Manufacture & Installation of Glass Reinforced Concrete (GRC Industry Group of NPCAA)

HDPE values obtained from experimental data using ASTM testing procedures.

300mm internal width

300mm internal width 300mm

internal width

300mm

internal width

ACO RESOURCES

ACO RESOURCES