|

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

ACO Drain

|

|

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

hh

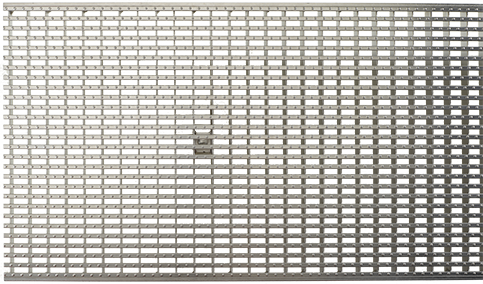

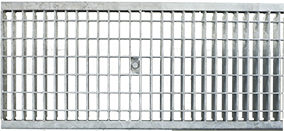

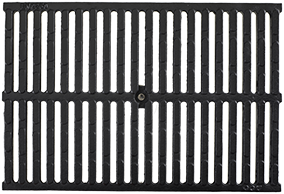

K300 / H300K Grates300mm QuickLok Trench Grates by Load

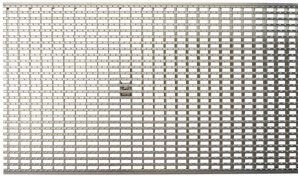

Notes: 1 - Meets ASME A112.6.3 Section 7.12 (American high heel standard). 300mm DrainLok Trench Drain Grates by Load

Notes: 1 - Meets ASME A112.6.3 Section 7.12 (American high heel standard). 2 - Denotes QuickLok grates. QuickLok bar included in grate Part Number. 300mm QuickLok Trench Grates Specification Information (Spec Info) Sheets

300mm DrainLok Trench Grates Specification Information (Spec Info) Sheets

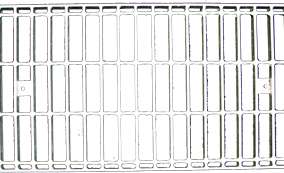

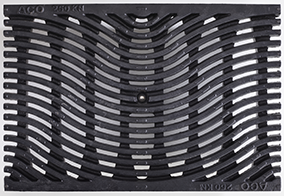

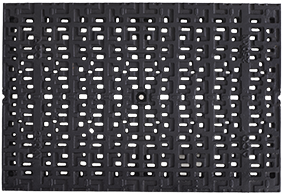

Heelsafe® Anti-Slip grates

A slip resistance classification is assigned to these grates. AS 4586 sets out three recognised tests that determine slip resistance: wet pendulum test (P-rating), wet-barefoot inclining platform test (A, B or C rating) and oil-wet inclining platform test (R-rating). HB 198 references AS 4586 by specifying the minimum slip resistance ratings dependent on the application. Grates with raised mechanical nodes have excellent durability compared with those produced by manufacturers who apply coatings or mechanically alter (bead blast etc...) to attain a level of slip resistance. These processes will not only ensure a short term slip resistance due to the wearing process but can introduce impurities in the material which will accelerate corrosion. ACO’s range of Heelsafe® Anti-Slip grates have raised mechanical nodes and are available in plastic, stainless steel and ductile iron, for more information visit www.heelsafe.co.nz

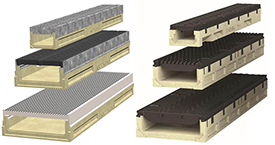

QuickLok locking system QuickLok

Comprised of a glass nylon stud, factory fitted to the grate, which allows a snap fit into a stainless steel spring clip in the locking bar. With no loose bolts or bars, QuickLok provides highly secure boltless locking, that is easy to remove/replace for maintenance and cleaning. Saves time and money during installation.

DrainLok locking system DrainLok - barless and boltless locking system

Fast locking device removes the need for bars and bolts and improves the channels hydraulic capacity. The DrainLok mechanism simply clips into the channel edge rail for quick installation. ACO’s DrainLok grates are fitted with anti–shunt lugs that restrict grate movement when installed, improving durability and longevity of the system.

|

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

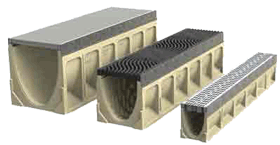

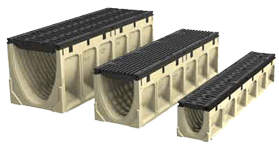

300mm internal width

300mm internal width 300mm

internal width

300mm

internal width

At ACO, we believe that pedestrian friendly grates and slip resistance go hand in hand. The grates with the trademark, Heelsafe® Anti-Slip comply to all four specific user requirements; heelsafe, wheelchair and walking cane safe, bicycle safe and are slip rated.

At ACO, we believe that pedestrian friendly grates and slip resistance go hand in hand. The grates with the trademark, Heelsafe® Anti-Slip comply to all four specific user requirements; heelsafe, wheelchair and walking cane safe, bicycle safe and are slip rated.