|

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

ACO Drain

|

|

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

hh

|

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

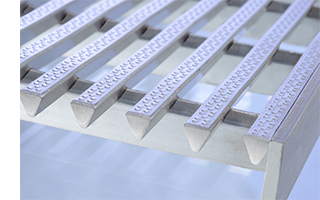

| Stainless 5 Star Heelsafe® Anti-Slip

June 2013 brought changes to the testing methods and classification of AS 4586: Slip resistance classification of new pedestrian surface materials. The accompanying handbook (HB 197) outlines the acceptable minimum standard of slip resistance in various pedestrian areas, such as walkways; shopping centres and supermarkets. HB 197 is a guide for selecting appropriate materials during specification of pedestrian surfaces. In order to assess how slip resistant a floor surface is, there are two tests specified within AS 4586: oil wet ramp and wet pendulum. |

Stainless 5 Star Heelsafe® Anti-Slip

|

Oil Wet Ramp (R-rating)

The Oil Wet Ramp test uses an inclining platform to assess the slip resistance of a material. The test determines the angle of inclination at which safe walking no longer occurs on the test surface, which is coated with engine lubricating oil. The test person moves back and forth across the test surface where the angle of inclination is increased until the safe limit of walking is reached.

The angle of inclination obtained is used to classify the degree of slip resistance with an ‘R’ rating, from R9 to R13. R9 is the lowest inclination rating the Standard classifies and is therefore the lowest slip resistance. (Refer to Table 2 for HB 197 recommended R-rating for pedestrian areas.)

Wet Pendulum test (P-rating)

The updated AS 4586, released in June 2013, shows the wet pendulum test having the most significant change in its test methodology and classification.

The Wet Pendulum test uses a Pendulum Friction Tester and a rubber slider. The rubber slider material has been altered in the 2013 Standard to more accurately represent a worn and polished heel. This means that the test is more difficult to achieve ‘higher’ levels of slip resistance than previous revisions of the Standard.

The classification methodology has also been changed: previously, the 2004 version of AS 4586 used V to Z classifications. This has been superseded by the 2013 release of AS 4586 with P1 to P5 classifications - P5 being the highest achievable level of slip resistance.

HB 197: An introductory guide to the slip resistance of pedestrian surface materials

HB 197 has not yet been updated to reflect the changes in wet pendulum classification of AS 4586 - 2013. In the interim, it is possible to draw parallel between the 2004 and 2013 Standards using the table (Table 1). Table 2 is taken from HB197 and makes recommendations for pedestrian surface materials in some locations. The column titled ‘Pendulum – 2013’ is an interpretation of the 2013 release of AS 4586 to compare with the 2004 classification. |

|

||||||||||||||||||||||

Table 2 |

||||

Location |

Pendulum - 2004 |

Pendulum - 2013 |

Ramp |

Stainless Wedgewire Heelsafe® Anti-Slip |

| External colonnade, walkways and pedestrian crossings | W |

P4 |

R10 |

|

| External ramps | V |

P5 |

R11 |

|

| Entry foyers hotel, office, public buildings - wet | X |

P3 |

R10 |

|

| Entry foyers hotel, office, public buildings - dry | Z |

P1 |

R9 |

|

| Shopping centre excluding food court | Z |

P1 |

R9 |

|

| Shopping centre – food court | X |

P3 |

R10 |

|

| Internal ramps, slopes (greater than 2 degrees) – dry | X |

P3 |

R10 |

|

| Lift lobbies above external entry level | Z |

P1 |

R9 |

|

| Other separate shops inside shopping centres | Z |

P1 |

R9 |

|

| Other shops with external entrances – entry area | X |

P3 |

R10 |

|

| Fast food outlets, buffet food servery areas | X |

P3 |

R10 |

|

| Hospitals and aged care facilities – dry areas | Z |

P1 |

R9 |

|

| Hospitals and aged care facilities – en suites | X |

P3 |

A or R10 |

|

| Supermarket aisles except fresh food areas | Z |

P1 |

R9 |

|

| Shop and supermarket fresh fruit and vegetable areas | X |

P3 |

R10 |

|

| Communal changing rooms | X |

P3 |

A¹ |

|

| Swimming pool surrounds and communal shower rooms | W |

P4 |

B¹ |

|

| Swimming pool ramps and stairs leading into water | V |

P5 |

C¹ |

|

| Toilet facilities in offices, hotels and shopping centres | X |

P3 |

R10 |

|

| Undercover concourse areas of sports stadium | X |

P3 |

R10 |

|

| Accessible internal stair nosings (dry) – handrails present | X |

P3 |

R10 |

|

| Accessible internal stair nosings (wet) – handrails present | W |

P4 |

B¹ or R11 |

|

| External stair nosings | W |

P4 |

R11 |

|

¹ Ratings for wet barefoot slip resistance test (AS 4586)

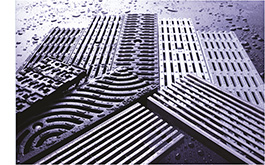

Heelsafe® Anti-Slip grates

To help prevent public falls and injuries, ACO believes that small slotted grates should also be slip resistant. Each grate complies to various user and legislative requirements, including AS 4586 for slip resistance. Heelsafe® Anti-Slip grates have raised mechanical nodes for tread durability and are available in a choice of stainless steel, ductile iron and plastic designs.

ACO believes that grates should be tested in two directions (parallel and perpendicular) as in pedestrian areas the direction travel is not always consistent.

Grates with raised mechanical nodes have excellent durability compared with those produced by manufacturers who apply coatings or mechanically alter (blast etc.) to attain a level of slip resistance. These processes will not only ensure a short term slip resistance due to the wearing process, but can introduce impurities in the material, which will accelerate corrosion.

Grates with raised mechanical nodes have excellent durability compared with those produced by manufacturers who apply coatings or mechanically alter (blast etc.) to attain a level of slip resistance. These processes will not only ensure a short term slip resistance due to the wearing process, but can introduce impurities in the material, which will accelerate corrosion.

For ease of identification of Heelsafe® Anti-Slip grates are identified by using this approved symbol. This symbol is a mark of compliance for pedestrian friendly grates: identifying grates suitable for heels, wheelchairs and bikes with a slip resistant rating.

New How to Video: Knockouts

New How to Video: How To Install In Line Pit Extension Riser Video

New How to Video: How To Fit PVC Pipe To In Line Pit

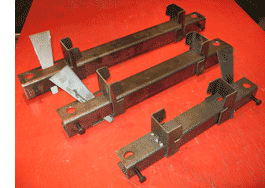

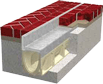

New Patented trench drainage installation device

New Patented trench drain installation device.

Installation devices for modular trench drains have been around for many years. Like other trench drain manufacturers, ACO has had a variety of installation devices over the years.

Installation devices for modular trench drains have been around for many years. Like other trench drain manufacturers, ACO has had a variety of installation devices over the years.

Many of these installation devices don’t work very well – whether they be bits of plastic molded on the side of channels or steel devices that the trench sits on, many of these devices are add-on after thoughts after the channel has been designed.

With the new generation of ACO Drain design, ACO has taken the opportunity to design the installation device in conjunction with the body of the channel. Apart from giving perfect alignment of joints and height the patented clamp locks two channels tight together as well as making sure the channels can’t float as the concrete is poured

around the channel.

The steel clamp mechanism works by using proven technology of a wedge to lock the device around the two channels. The installation device is bolted to two pieces of rebar or other rod support the channels leaving a gap under the channel for the concrete haunch. The installation device is ‘lost’ within the concrete haunch.

The steel clamp mechanism works by using proven technology of a wedge to lock the device around the two channels. The installation device is bolted to two pieces of rebar or other rod support the channels leaving a gap under the channel for the concrete haunch. The installation device is ‘lost’ within the concrete haunch.

The new ACO Drain installation device is available that fits both K100 and S100K 4” internal width channels. A slightly larger devise fits both the K200and S200K and the largest device fits K300 &S300K.

For more information please contact your local ACO sales office.

300mm internal width

300mm internal width 300mm

internal width

300mm

internal width

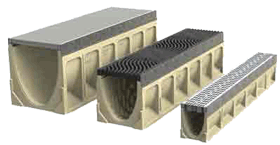

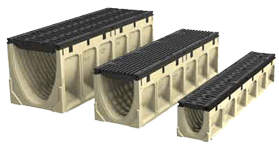

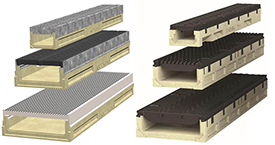

ACO, global leader and pioneer of the modular polymer concrete trench drain, has launched a comprehensive range of new ACO Drain® systems to deal with modern challenges experienced by today’s designers.

ACO, global leader and pioneer of the modular polymer concrete trench drain, has launched a comprehensive range of new ACO Drain® systems to deal with modern challenges experienced by today’s designers. Draining large flat pavements efficiently is also challenging. ACO’s new signature Polycrete

Draining large flat pavements efficiently is also challenging. ACO’s new signature Polycrete Heelsafe

Heelsafe To help prevent public falls and injuries, ACO believes that small slotted grates should also be slip resistant.

To help prevent public falls and injuries, ACO believes that small slotted grates should also be slip resistant.

Draining flat pavements efficiently is challenging. ACO’s new signature

V-shaped Polycrete

Draining flat pavements efficiently is challenging. ACO’s new signature

V-shaped Polycrete