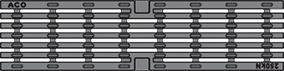

100mm grates |

Length

mm |

Part

No. |

Wgt

(kg) |

|

Spec

Info

|

| LOAD CLASS A - AS 3996 - 10kN - approximate wheel load 330kg |

|

Type 494Q Black

Plastic Intercept

Heelsafe® Anti-Slip |

500 |

97393 |

0.8 |

|

|

|

|

|

|

Type 495Q Grey

Plastic Intercept

Heelsafe® Anti-Slip |

500 |

97385 |

0.8 |

|

|

|

|

|

|

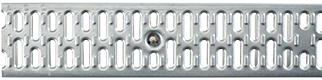

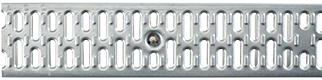

Type 420Q/421Q

Galv Slotted |

1000

500 |

31530

31531 |

2.7

1.4 |

|

|

|

|

|

|

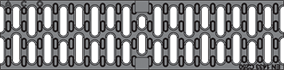

Type 450Q/452Q

Stainless Slotted |

1000

500 |

31630

31631 |

2.7

1.4 |

|

|

|

|

|

|

Type 445Q/446Q

Stainless Wedgewire

Heelguard® 1 |

1000

500 |

141202

141204 |

2.5

1.3 |

|

|

|

|

|

| LOAD CLASS B - AS 3996 - 80kN - approximate wheel load 2,670kg |

|

Type 447Q/448Q

Stainless Wedgewire1

Heelsafe® Anti-Slip |

1000

500 |

98971

98991 |

3.2

1.6 |

|

|

|

|

|

|

Type 443Q/444Q

Stainless 5 Star1

Heelsafe® Anti-Slip |

1000

500 |

141138

141139 |

3.2

1.6 |

|

|

|

|

|

| LOAD CLASS D - AS 3996 - 210kN - approximate wheel load 8,000kg |

|

Type 492Q

Composite Slotted1

Heelsafe® Anti-Slip |

500 |

31710 |

1.0 |

|

|

|

|

|

|

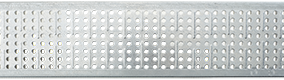

Type 411Q/413Q

Galv Perforated

|

1000

500 |

98905

98918 |

5.1

2.6 |

|

|

|

|

|

|

Type 465Q/466Q

Stainless Perforated |

1000

500 |

98927

98957 |

5.1

2.6 |

|

|

|

|

|

|

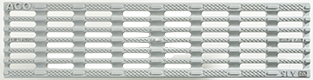

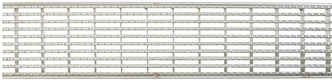

Type 425Q/426Q

Galv Slotted |

1000

500 |

31540

31541 |

4.0

2.0 |

|

|

|

|

|

|

Type 455Q/457Q

Stainless Slotted |

1000

500 |

31640

31641 |

4.0

2.0 |

|

|

|

|

|

|

Type 405/406Q

Galv Mesh |

1000

500 |

141739

141740 |

4.3

2.2 |

|

|

|

|

|

|

Type 430Q/431Q

Stainless Mesh |

1000

500 |

141744

141745 |

4.1

2.1 |

|

|

|

|

|

|

Type 480Q

Iron Wave

Heelsafe® Anti-Slip |

500 |

97118 |

4.5 |

|

|

|

|

|

|

Type 481Q

Iron Decorative

Heelsafe® Anti-Slip |

500 |

97120 |

4.1 |

|

|

|

|

|

|

Type 461Q

Iron Slotted |

500 |

141122 |

4.6 |

|

|

|

|

|

|

Type 478Q

Iron Intercept1

Heelsafe® Anti-Slip |

500 |

03314 |

5.8 |

|

|

|

|

|

|

Type 477Q Iron

Galv Intercept1

Heelsafe® Anti-Slip |

500 |

141751 |

5.8 |

|

|

|

|

|

Notes:

1 - Meets ASME A112.6.3 Section 7.12 (American high heel standard).

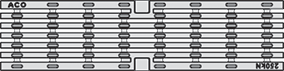

100mm grates |

Length

mm |

Part

No. |

Wgt

(kg) |

|

Spec

Info |

|

| LOAD CLASS A - AS 3996 - 10kN - approximate wheel load 330kg |

|

Type 494D Black

Plastic Intercept

Heelsafe® Anti-Slip |

500 |

142459 |

0.8 |

|

|

|

|

|

|

|

Type 495D Grey

Plastic Intercept

Heelsafe® Anti-Slip |

500 |

142460 |

0.8 |

|

|

|

|

|

|

|

Type 420D/421D

Galvanised Slotted |

1000

500 |

12610

12611 |

2.7

1.4 |

|

|

|

|

|

|

|

Type 450D/452D

Stainless Slotted |

1000

500 |

12640

12641 |

2.7

1.4 |

|

|

|

|

|

|

| LOAD CLASS B - AS 3996 - 80kN - approximate wheel load 2,670kg |

|

Type 443D/444D

Stainless 5 Star1

Heelsafe® Anti-Slip |

1000

500 |

142217

142218 |

3.2

1.6 |

|

|

|

|

|

|

|

Type 435D/436D

Stainless Longitudinal

Heelsafe® Anti-Slip |

1000

500 |

132556

132551 |

4.0

2.0 |

|

|

|

|

|

|

|

Type 438D/437D Galvanised Longitudinal1

Heelsafe® Anti-Slip |

1000

500 |

132555

132550 |

4.0

2.1 |

|

|

|

|

|

|

| LOAD CLASS D - AS 3996 - 210kN - approximate wheel load 8,000kg |

|

Type 492D

Composite Slotted1

Heelsafe® Anti-Slip |

500 |

132720 |

1.0 |

|

|

|

|

|

|

|

Type 425D/426D

Galvanised Slotted |

1000

500 |

12614

12615 |

4.0

2.0 |

|

|

|

|

|

|

|

Type 455D/457D

Stainless Slotted |

1000

500 |

12644

12645 |

4.0

2.0 |

|

|

|

|

|

|

|

Type 405Q/406Q

Galvanised Mesh2 |

1000

500 |

142401

142402 |

4.3

2.2 |

|

|

|

|

|

|

|

Type 430Q/431Q

Stainless Mesh2 |

1000

500 |

142403

142404 |

4.1

2.1 |

|

|

|

|

|

|

|

Type 480D

Iron Wave1

Heelsafe® Anti-Slip |

500 |

142461 |

4.5 |

|

|

|

|

|

|

|

Type 460D

Iron Slotted |

500 |

12670 |

4.6 |

|

|

|

|

|

|

|

Type 476D

Iron Intercept1

Heelsafe® Anti-Slip |

500 |

142171 |

4.8 |

|

|

|

|

|

|

|

Type 475D Iron

Galvanised Intercept1

Heelsafe® Anti-Slip |

500 |

142172 |

4.8 |

|

|

|

|

|

|

Notes:

1 - Meets ASME A112.6.3 Section 7.12 (American high heel standard).

2 - Denotes QuickLok grates. QuickLok bar included in grate Part Number.

At ACO, we believe that pedestrian friendly grates and slip resistance go hand in hand. The grates with the trademark, Heelsafe® Anti-Slip comply to all four specific user requirements; heelsafe, wheelchair and walking cane safe, bicycle safe and are slip rated.

At ACO, we believe that pedestrian friendly grates and slip resistance go hand in hand. The grates with the trademark, Heelsafe® Anti-Slip comply to all four specific user requirements; heelsafe, wheelchair and walking cane safe, bicycle safe and are slip rated.

A slip resistance classification is assigned to these grates. AS 4586 sets out three recognised tests that determine slip resistance: wet pendulum test (P-rating), wet-barefoot inclining platform test (A, B or C rating) and oil-wet inclining platform test (R-rating). HB 198 references AS 4586 by specifying the minimum slip resistance ratings dependent on the application.

Grates with raised mechanical nodes have excellent durability compared with those produced by manufacturers who apply coatings or mechanically alter (bead blast etc...) to attain a level of slip resistance. These processes will not only ensure a short term slip resistance due to the wearing process but can introduce impurities in the material which will accelerate corrosion.

ACO’s range of Heelsafe® Anti-Slip grates have raised mechanical nodes and are available in plastic, stainless steel and ductile iron, for more information visit www.heelsafe.co.nz

QuickLok

Comprised of a glass nylon stud, factory fitted to the grate, which allows a snap fit into a stainless steel spring clip in the locking bar. With no loose bolts or bars, QuickLok provides highly secure boltless locking, that is easy to remove/replace for maintenance and cleaning. Saves time and money during installation.

Locate locking bar in recesses, rotate and use hammer to tap securely into place. Serrated ends grip in recess. |

|

K200/K300 channels use plastic safety clip to hold in place. |

|

To install grate, align QuickLok stud directly over locking bar. |

|

Push down or stand on grate until it clicks into position. |

|

To remove first grate, insert grate removal tool into slots at end of grate, pull up sharply. Rest of grates can be removed by hand. |

|

To remove bar, insert screwdriver into hole at end of bar and lever back serrated end, rotate bar free. |

DrainLok - barless and boltless locking system

Fast locking device removes the need for bars and bolts and improves the channels hydraulic capacity. The DrainLok mechanism simply clips into the channel edge rail for quick installation. ACO’s DrainLok grates are fitted with anti–shunt lugs that restrict grate movement when installed, improving durability and longevity of the system.

Position grate onto channel and align anti–shunt lugs with the recess in the rail. |

|

Push down or stand on the grate until it clicks into position. |

|

To remove first grate, insert grate removal tool into slots at the end of the grate and pull up sharply. Remaining grates can be removed by hand. |

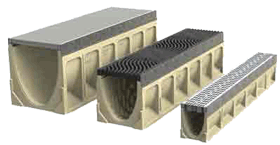

300mm internal width

300mm internal width 300mm

internal width

300mm

internal width

At ACO, we believe that pedestrian friendly grates and slip resistance go hand in hand. The grates with the trademark, Heelsafe® Anti-Slip comply to all four specific user requirements; heelsafe, wheelchair and walking cane safe, bicycle safe and are slip rated.

At ACO, we believe that pedestrian friendly grates and slip resistance go hand in hand. The grates with the trademark, Heelsafe® Anti-Slip comply to all four specific user requirements; heelsafe, wheelchair and walking cane safe, bicycle safe and are slip rated.